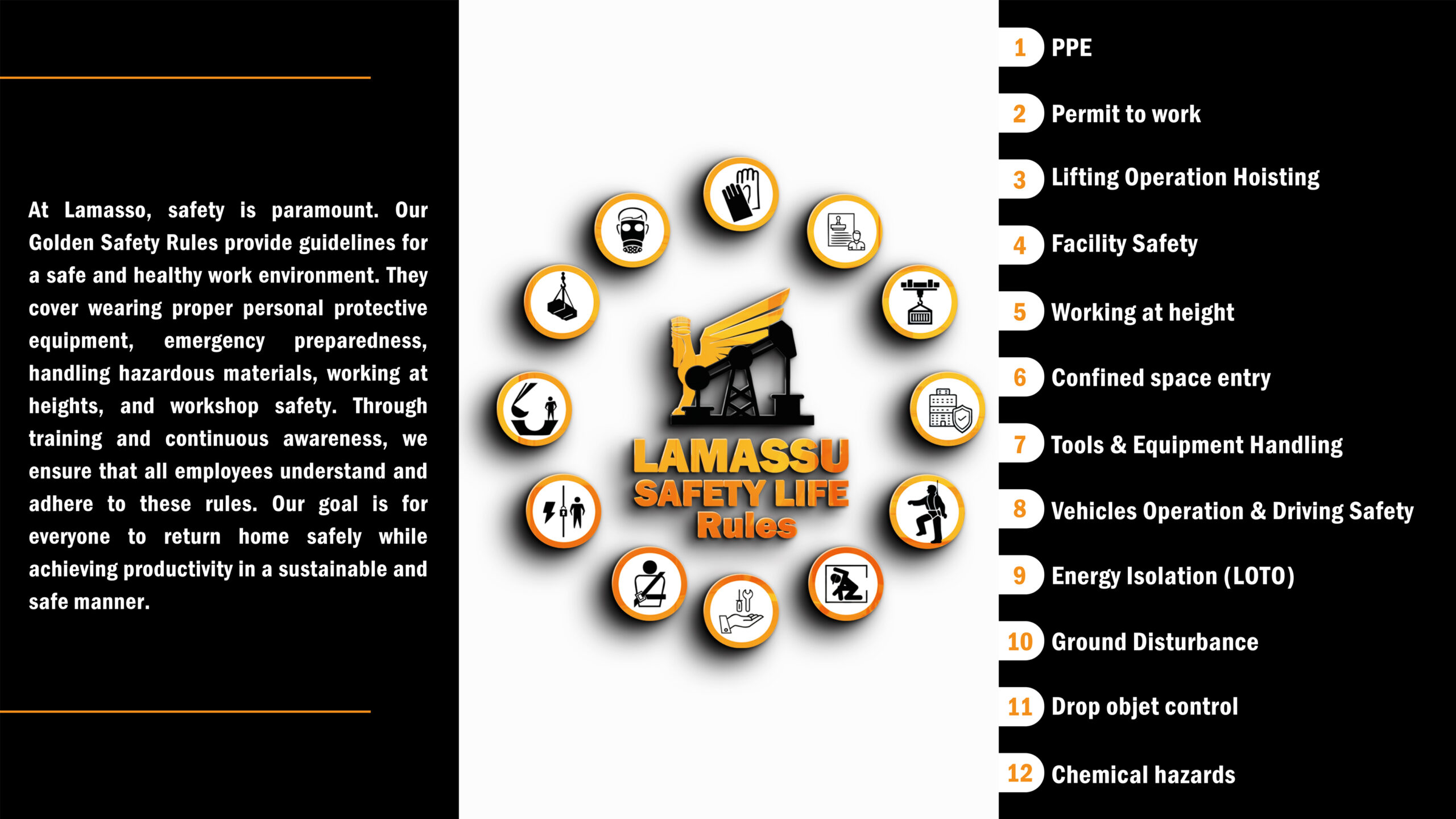

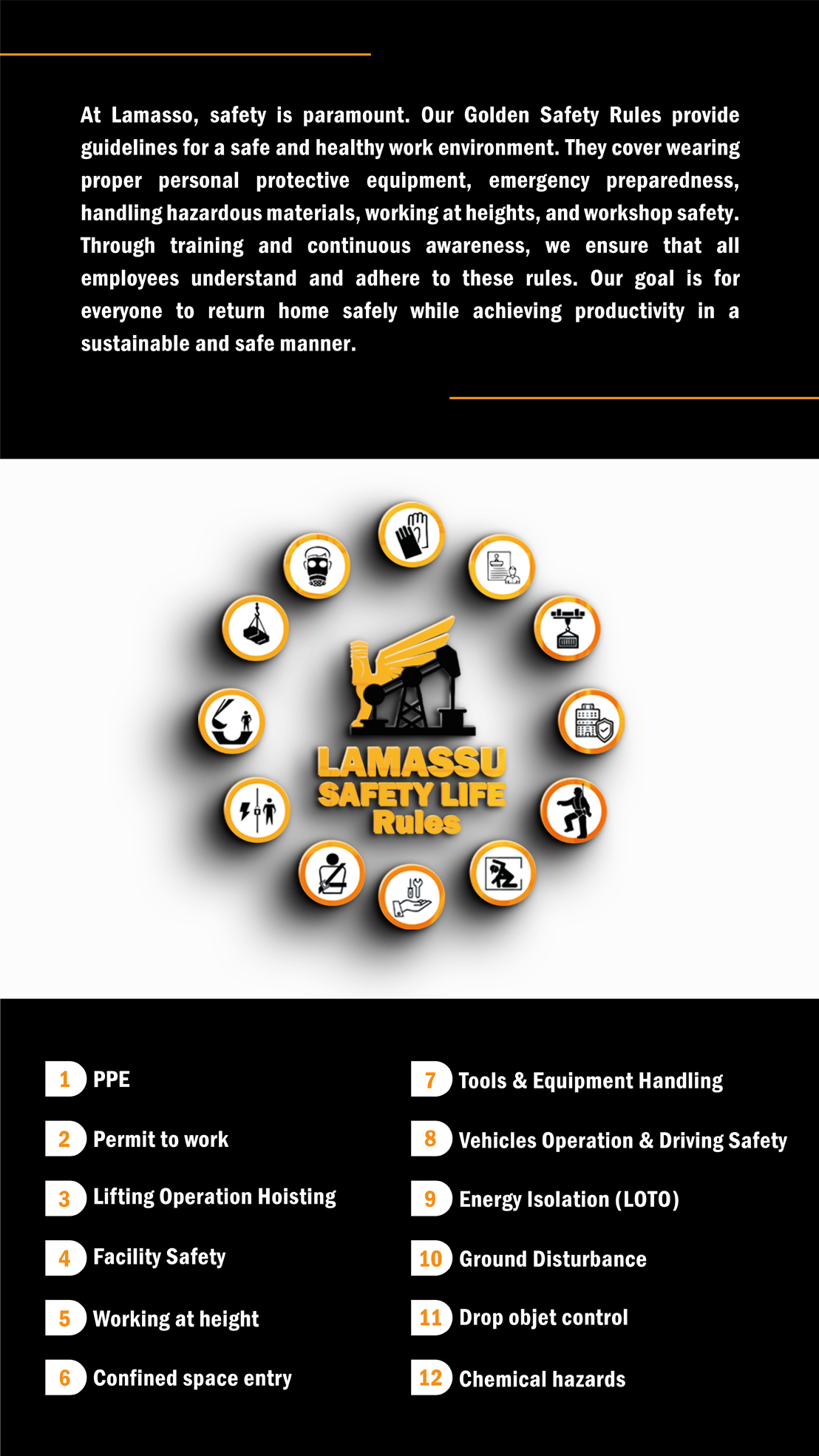

SAFETY LIFE RULES

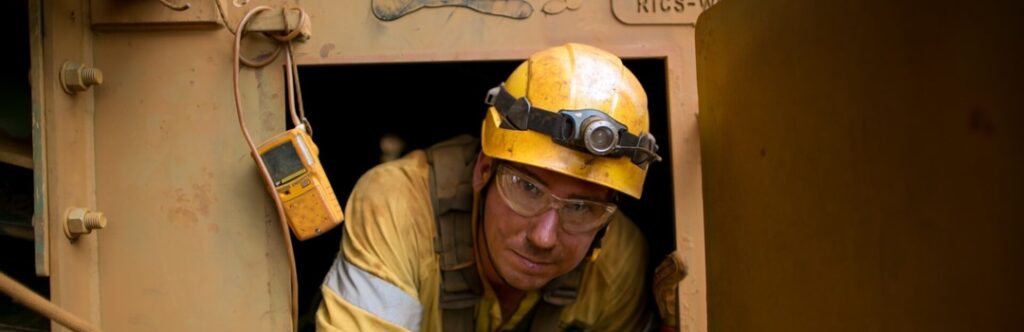

1 - PPE:

This rule is crucial for ensuring the safety of workers on-site. (PPE) includes items like helmets, safety glasses, gloves, and safety shoes, which are necessary to protect workers from various hazards. For instance, helmets protect against head injuries from falling objects, safety glasses shield the eyes from flying debris, gloves prevent cuts and burns, and safety shoes offer protection from heavy objects or sharp materials. By enforcing the use of PPE, employers aim to prevent injuries and accidents, promoting a safer work environment.

2 - Permit to work:

This rule emphasizes the importance of obtaining prior permission before undertaking specific tasks on-site. Tasks like welding, cutting, or working in confined spaces can pose significant risks if not performed correctly. The Permit to Work system ensures that these tasks are carried out safely and in compliance with specified standards. It involves a formal process where workers obtain authorization from relevant authorities, which may include safety supervisors or managers, before commencing work. This helps in identifying potential hazards, implementing necessary controls, and reducing the risk of accidents or injuries.

3 - Lifting Operation & Hoisting:

This rule focuses on the safety of lifting and hoisting operations, which are common tasks on construction sites and industrial facilities. Proper equipment and procedures are essential to prevent accidents such as dropped loads or equipment failure. Workers involved in lifting operations must use appropriate lifting equipment, such as cranes or forklifts, and follow established safety protocols. This includes inspecting equipment before use, securing loads properly, and ensuring clear communication among the team to avoid accidents and injuries.

4 - Facility Safety:

Facility safety encompasses various measures aimed at ensuring the safety of buildings, structures, and premises in general. Regular maintenance, inspections, and the implementation of appropriate safety procedures are essential aspects of facility safety. This includes repairing damaged infrastructure, maintaining fire safety systems, and providing adequate lighting and signage to prevent accidents. By prioritizing facility safety, employers create a secure environment for workers and visitors, reducing the risk of incidents and ensuring compliance with safety regulations.

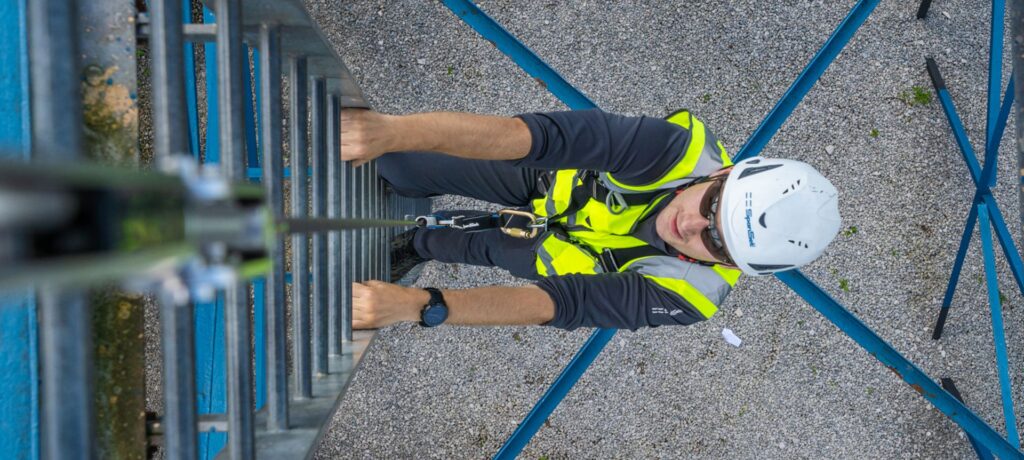

5 - Working at height:

Working at elevated heights presents significant risks, including falls and injuries. This rule addresses the safety of workers who perform tasks such as construction, maintenance, or repair work at height. Proper training on safe climbing and descending techniques, as well as the use of fall protection equipment like harnesses and guardrails, are crucial. Employers must also ensure that workers are aware of the hazards associated with working at height and take appropriate precautions to mitigate these risks.

6 - Confined space entry:

Confined spaces pose unique hazards due to limited entry and exit points, poor ventilation, and potential exposure to harmful substances. This rule focuses on ensuring the safety of workers who need to enter confined or restricted spaces for tasks such as maintenance or inspection. Safe entry and exit procedures, including the use of permits and proper ventilation, are essential to prevent accidents like suffocation or exposure to toxic gases. Workers must also be equipped with appropriate protective gear and trained on emergency procedures to respond effectively in case of an incident.

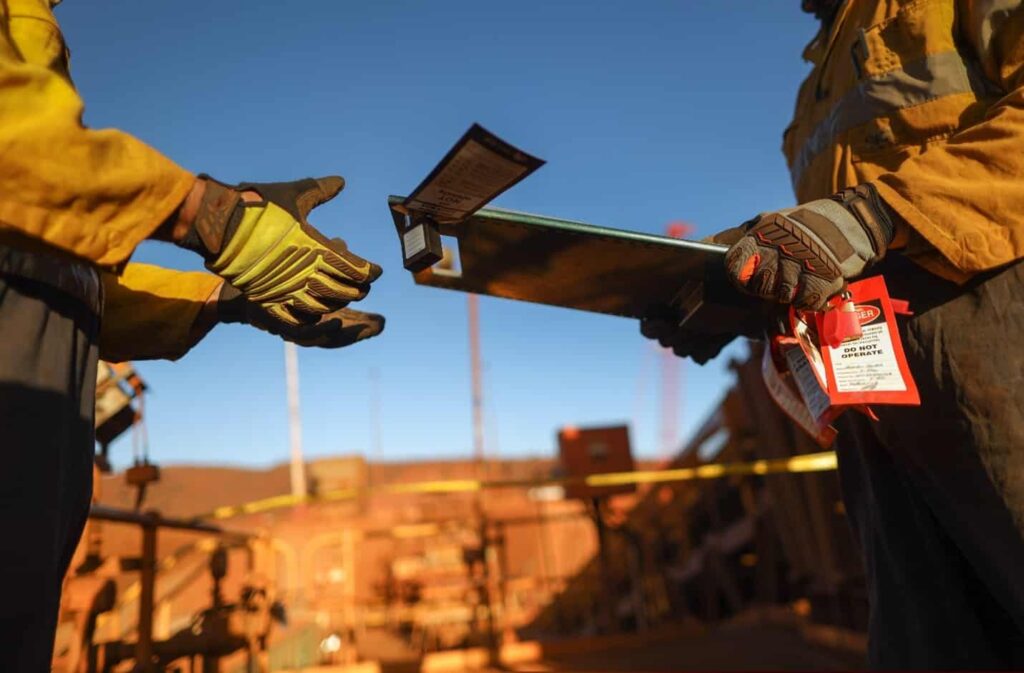

7 - Energy Isolation:

Energy isolation, also known as lockout/tagout, is a critical safety procedure to prevent the unexpected startup of machinery or equipment during maintenance or repair work. This rule requires workers to isolate energy sources by disconnecting or locking them out and using warning signs or tags to indicate that maintenance is in progress. By effectively isolating energy, employers reduce the risk of electrical shocks, equipment malfunctions, and other accidents that could cause serious injuries or fatalities.

8 - Ground Disturbance:

Ground disturbance activities, such as excavation or drilling, can pose risks to workers and underground infrastructure like pipes and cables. This rule aims to ensure ground safety and minimize the impact of work on soil stability and underground utilities. Workers must follow procedures to locate and identify underground services, use proper excavation techniques, and implement measures to prevent collapses or damage to underground infrastructure. By prioritizing ground disturbance safety, employers protect workers and prevent costly damages to essential services.

9 - Tools & Equipment Handling:

Safe handling of tools and equipment is essential to prevent injuries and maintain productivity on-site. This rule emphasizes proper storage, maintenance, and use of tools and equipment to minimize the risk of accidents. Workers should be trained on the correct procedures for handling tools, including inspection before use, proper lifting techniques, and appropriate storage to prevent tripping hazards. Regular maintenance and servicing of equipment also ensure that they remain in good working condition, reducing the likelihood of malfunctions or accidents.

10 - Vehicles Operation & Driving Safety:

Vehicle operations on-site require strict adherence to safety rules to prevent accidents and injuries. This rule emphasizes safe driving practices, regular vehicle maintenance, and the use of appropriate safety equipment like seat belts and helmets. Operators must be trained and licensed to operate vehicles safely, and speed limits and traffic rules should be enforced within the site. By prioritizing vehicle safety, employers reduce the risk of collisions, pedestrian accidents, and damage to property.

11-Drop objet control:

Drop object control is a crucial safety measure aimed at preventing objects from falling and causing harm to workers, equipment, or the environment within a worksite. It involves identifying potential hazards related to falling objects and implementing measures to control and mitigate these risks.

12-Chimecal Hazards:

Chemical hazards present risks such as toxicity, flammability, and chemical burns, which can have serious consequences if not managed properly. This rule requires identifying chemical hazards present on-site and implementing appropriate preventive measures to protect workers and the environment. This includes storing chemicals safely, providing adequate ventilation, and using personal protective equipment (PPE) such as gloves, goggles, and respirators when handling hazardous substances. Training on the safe handling and disposal of chemicals is also essential to minimize the risk of accidents and exposure.